|

The U.S. Computer Printer Industry |

||

|

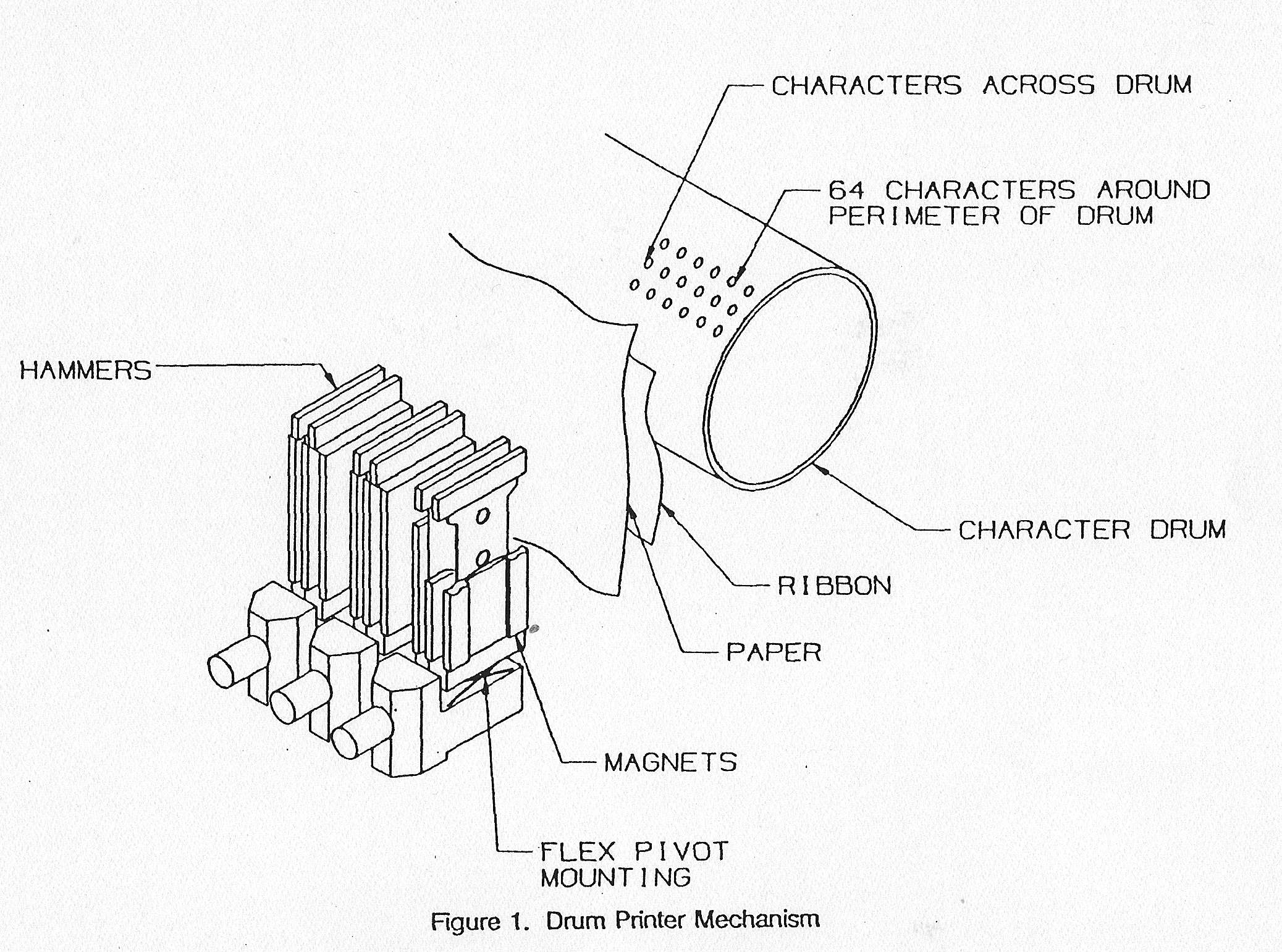

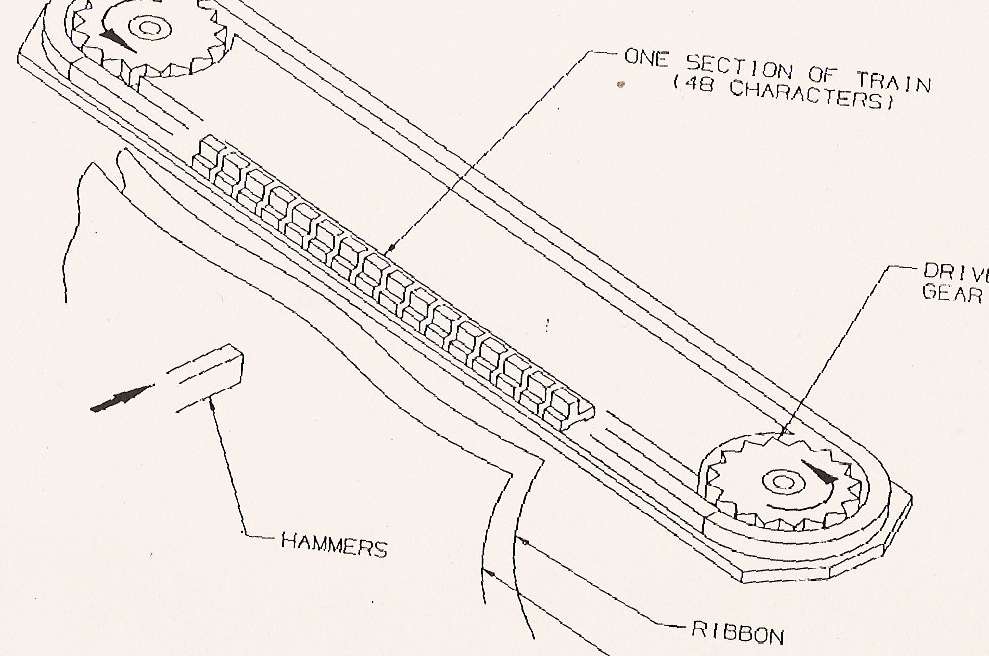

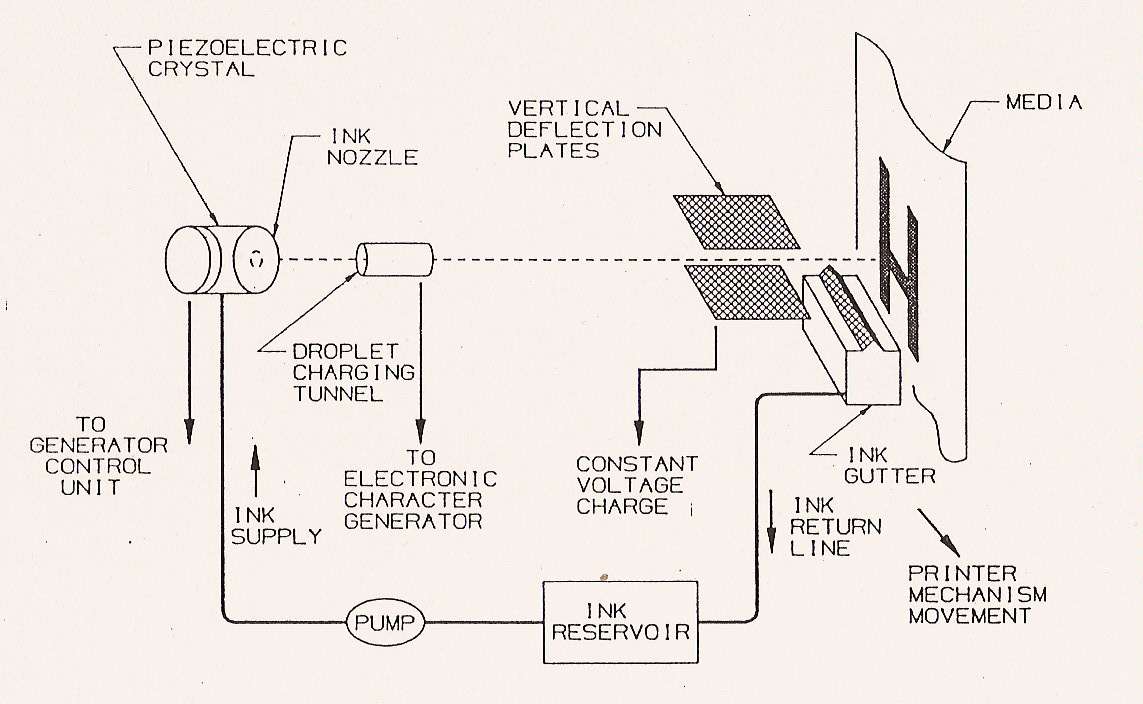

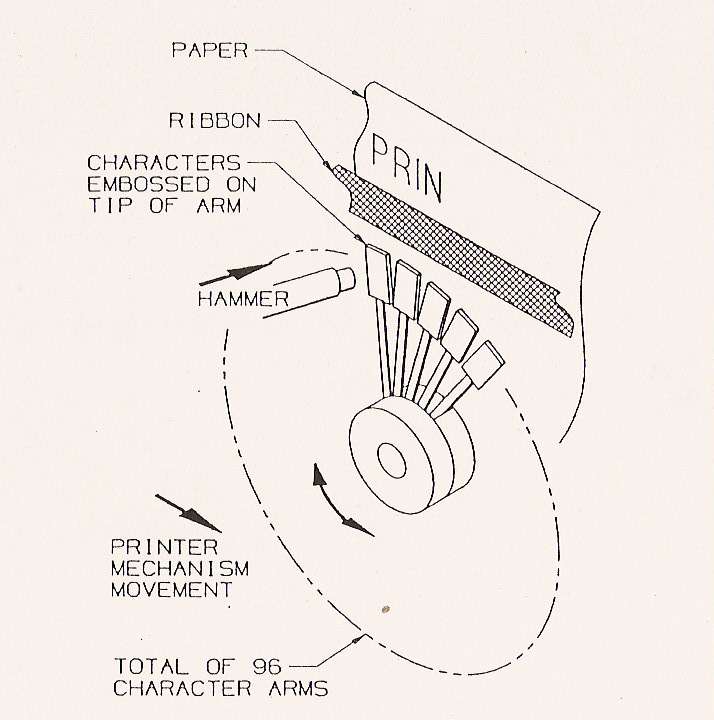

Abstract. This paper reviews the history of the computer printing industry in the United States since World war Il. The wide variery of printer technology introduced is surveyed and differentiating product characteristics described. The relationship of computer technology to printer technology and of the computer industry to the printer industry is discussed. Automatic data processing in the United States is generally thought to have started with the mechanization of the 1890 U.S. population census by means of Hollerith punch card machines. Output for the original Hollerith system consisled sim ply of a clerk reading and noting on paper the card count displayed on a bank of accumulating counters called the 'tabulating machine'. Automatic printing did not start until 1906. when the first printing tabulator was developed by the U.S. Government at the Bureau of the Census. [Truesdell 1965]. Hollerith's company. The Tabulating Machine Company which was the predecessor to International Business Machines (IBM), did not introduce ils first printing tabulator until 1921. [Austrian 1982]. The use of punch card accounting spread widely in the years between World War 1 and World War II. By the 1930's the punch card was the commonly found method of data processing in larger commercial enterprises and government bureaus. And the term tabulator, had come to mean a machine which accumulated totals and printed them on paper. 1946-1950 The period immediately after World War Il was one in which a numbcr of govcrnment laboratories, universities and small private companies designed and built the first stored program electronic digital computers. Without exception. these early design teams chose to use readily available commercial equipment for printing. For example, ENIAC used standard card punching equipment manufactured by IBM for input/output. Data was fed into the machine using a card reader and taken out by means of a summary punch. The cards were then printed out on a standard tabulating machine. ENIAC used the 405 punched card tabulator, a machine IBM first introduced in 1934. The 405 printed both alphabetic and numeric characters by means of vertical type bars and could print at 80 lines per minute (lpm). The print head contained 88 type bars, the leftmost 43 for alphanumeric characters and the remaining 45 for numeric characters only. [Bashe et al. 1986] ln July 1949, IBM announced a successor tabulator, the model 407. This machine was also used as an output printer on early computers. ln the 407, the 88 bars of the 405 were replaced with 120 print wheels. Each wheel carried 48 characters on its periphery. The print speed was 150 lpm. The wheels were rotated until the desired character to be printed was positioned on the print line, the rotation was then in effect stopped and the entire line of wheels caused to impact the ribbon and paper. [Bashe et al. 1986] ln addition to punch card tabulators, various commercially available electric typewriters were used as printers with early computers. Among these were Teletype machines, the Friden Flexowriter and the Remington and IBM typewriters. 1950-1959 The 1950 decade was the period in which initial computer commercialization took place and products replaced projects. Remington Rand, which had acquired the Eckert Mauchly company, was the first commercial provider of large scale computers. The first Univac l, a decimal machine designed for data processing, was delivered to the U.S. Government in 1951. ln late 1952, Remington Rand delivered to the government the first ERA 1101, an advanced scientific computer. The first Univac for strictly commercial applications was installed in 1954. ln the spring of 1953, IBM delivered its first large scale scientific computer, the model 701, to the U.S. Government. IBM then shipped a 701 per month for the next 18 months, a tremendous accomplishment. IBM, also in 1953, announced a small commercial electronic computer. This was the model 650 magnetic drum calculator, with direct punch card input and output. The model 650 machine was a success and ultimately about 1800 were delivered. Univac's input/output system was designed around its innovative magnetic tape units. Univac regarded punch cards as obsolete or at best transitional. Input/output for early IBM computers, on the other hand, relied on IBM's strength - punch cards. IronicaIly, in 1956, IBM started the long term demise of punch cards when it introduced the model 305 RAMAC, the first magnetic disk storage unit. ln the next five years, a series of large scale machines, the 702, 704, 705 and 709, aIl part of what has come to be called the 'first generation' (i.e., non-transistor), followed from IBM. Univac answered the IBM product flow. ln large scale machines, it introduced an improved Univac II and the ERA 1105. ln smaller machines, Univac produced both the File Computer and the Solid State Computer. Univac and IBM remained the major suppliers and competitors during the 1950's. Other companies, both weIl established and new start-ups, tried to enter the computer business during the period. ln the latter half of the decade they started to make their presence felt. HoneyweIl, General Electric, National Cash Register, RCA, Philco, Bendix and Burroughs were some of the familiar names. The 1950's were characterized by rapid technological innovation in aIl aspects of computing. By far the most significant of these was the transistor. The commercial production of transistors made possible an order of magnitude increase in capacity, speed and reliability. Within a few years aIl non-transistor computing machines were obsolete. An influential industrial development of the period worthy of note was the emergence of a group of smaller companies, known as OEM (Original Equipment Manufacturer) suppliers. Computer Output Printing Printing techniques, as applied to computers, fall into two broad classifications: impact and nonimpact depending on the mode of transfer of ink to the paper. Printers can also be divided into those which have a set of preformed (fully formed) characters and those which form the chracters from a matrix of dots. Printers can also be divided by their speed into serial (slow) and parallel (fast). The faster parallel machines print a line at a time and hence are called line printers. Fast Printers Customer interest in a printer in the range of 1000 lpm was recognized within IBM and Univac in the early 1950's. ln 1952, Univac announced its High Speed Off Line Printer System. This consisted of a magnetic tape unit, a memory and control unit, a power supply and the first high speed drum line printer. The printer operated at 600 lpm. [Clamons 1988]. The drum is a logical extension of the wheels used in tabulators with the wheels fixed together. The increased speed is achieved by rotating the drum continuously instead of stopping each time it is desired to print. Printing is accomplished by forcing the paper and ribbon into the drum at the correct instant by means of print hammers or actuators. This is known as printing on the fly. (see Figure 1). Soon after the Univac announcement, drum line printers were announced by OEM suppliers such as Potter Instruments, Anelex and Shepard Laboratories. Early drum line printers had speeds ranging from 300 to 1000 lpm. Print quality was minimally acceptable. Character smear and blur were common as were wavy print lines. Smear was due to the font moving while under the hammer and wavy print lines were produced by variability of hammer flight time. To avoid these problems of printing on the fly, dot matrix techniques were tried. ln 1954, Burroughs announced a 1000 lpm wire printer. Each character was formed by the combination of dots printed by selected wire from a 5×7 array. ln June 1955, IBM announced two such wire printers capable of printing at 1200 lpm. These machines performed marginally and were withdrawn from the marketplace within a few years. Slow Printers Serial printers were used where their lower speed was adequate and/or cost a significant factor. The most common of these were the Teletype machines such as the Model 15 and, after 1954, the Model 28. These machines had speeds of 100 words per minute or roughly 10 characters per second (cps). (see Figure 2). Nonimpact Printers Long before the advent of computers, it was weIl known that a wide range of physical phenomena was adaptable to nonimpact printing on paper. By the 1950's, a variety of nonimpact prototypes were to be found in the field. However, these early printers exhibited undesirable characteristics such as; high cost, lack of software, complexity, and poor reliability. Most approaches required custom electronic components, advances in the field of electrophotographic materials and specially treated paper. The first successful nonimpact printer was the Whippet built by Burroughs in 1956 for military applications.[Clamons 1988]. It was a direct electrostatic printer which used a special dielectric paper. Approximately 100 Whippet printers were delivered to the U.S. armed services. (See Figure 3). A number of other commercial non impact printers were introduced in the 1950's. but none found wide acceptance. IBM introduced a nonimpact photographic printer in 1956 for printing on punch cards. [Clamons 1988]. NCR introduced a similarly unsuccessful printer which relied on magnetic transfer and heat processing. The fastest printer introduced in the the 1950's was an electrophotographic machine introduced by Stromberg Carlson. On]y a few of this 5000 lpm machine were sold. 1960-1969 The computer industry as we know it today was defined during the 1960's. This decade saw the development of second generation computers which were fully transistorized and used programming languages. These products were soon followed by the introduction of families of fully compatible computers. ln 1960 alone, Univac announced three, new large scale solid state computers. And by 1962, IBM had completely replaced its 700 series vacuum tube product line with its 7000 series transistorized machines. An important development early in the decade, was IBM's introduction of the model 1401, the successor to its first generation model 650. The 1401 had much improved price performance and won quick commercial acceptance. During its life cycle, about 15,000-20,000 of these machines were installed. As a benchmark, at the time of the 1401 announcement, a total of about 6,000 computers had been installed in the U.S. The 1401 system included an important new line printer, the model 1403 chain printer. This machine set a new de facto standard for the industry and positioned IBM as the technological leader in impact printer products. Il was so successful that it proved to be a major contributor to the popularity of the 1401 causing sales to far exceed IBM's expectations. [Fisher et al p. 52-3)]. At the start of the 1960's, the U.S. competitors to IBM and Univac were Honeywell, Burroughs, RCA, NCR, GE and to a lesser degree Philco and Control Data. These usually turned to OEM suppliers for their printer requirements, primarily Anelex for line printers and Teletype for terminaIs. An important industrial development of the decade was the emergence of the minicomputer companies. Among them, Digital Equipment Corporation (DEC), Scientific Data Systems (SDS), and Computer Control Corp (CCC). These were new, smaller electronics based companies. They avoided commercial data processing and offered transistorized computers with minimal software and peripherals for use in digital electronic systems. The major event of the later 1960's was IBM's introduction of a powerful range of software compatible computers, the IBM 360 system. This bold action served to establish IBM's leadership of the computer industry worldwide. Line Printers IBM's 1403 chain printer derived its name from ils horizontal font carrier which consisted of type slugs connected together to form a chain. (see Figure 3). When the character to be printed reached the proper column, the hammer was fired impacting the type, ribbon and paper. The 1403 print quality was superior to drum printers due to faster print hammers which reduced the smear. ln addition, variations of hammer flight time resulted in horizontal rather than vertical displacement of print, an effect to which humans are more accustomed. The growth of the EDP market and the emergence of the minicomputer market engendered a number of new OEM peripheral equipment suppliers. Among these was Dataproducts Corporation, an OEM printer supplier, formed in 1962. Dataproducts first line printer was a drum printer which provided superior print quality and improved reliabiIity at reduced cost due to a unique fast hammer mechanism invented by Clifford J. Relms. [Wieselman 1975]. The Helms invention was an impact slug mounted on a flat coil positioned between two permanent magnets and suspended by flex-pivoted springs which also acted as electrical conductors to the coiI. The design provided both shorter contact time and uniform flight time so that smear was reduced and print lines were straight. The early line printer market was small and ill-defined and not surprisingly market data is difficult to obtain. Dataproducts corporate archives reveal that the company shipped 39 line printers in 1963, the first year of production. Shipments increased more than tenfold to the grand total of 474 units by 1969. Low Speed Printers The most popular low speed printer of the decade was the inexpensive 10 cps Teletype Model 33 communications terminal, introduced in 1962. Il sold in the $500 range and included a key board, punch tape reader/punch and printer. Over 500,000 were produccd by 1975. The Model 33 was used both directly connected (on-line) and via punched paper tape (off-line). Another popular low speed printer was the IBM Selectric typewriter. Originally introduced as an office typewriter, its first computer application was in 1961 as a console printer for the IBM Stretch. The Selectric was a 10 cps seriaI printer which used a sphere, popularly known as the golfball, as the font carrier. At about $1000, it was more costly than the Model 33 but offered the advantages of better print quality and operator changeable fonts. Another serial printer in relatively common use was the Friden Flexowriter. Its price was nearly three times that of the Teletype Model 33 but its quality, reliability and system flexibility made it easier to integrate into larger systems. A seriaI dot matrix printer was developed in 1964 by the Epson Corporation for the Olympic games in Tokyo. However, Epson did not introduce its production MX printer series for minicomputers until twelve years later. Nonimpact Printers The first commercially successful application of nonimpact printer technology was the A. B. Dick Company 'Videograph'. First delivercd in 960, it printed address labels at 14,000 lpm (about 36 labels per second) on 3 inch wide, dielectric paper. [Stone 1988]. Imaging was accomplished using a custom cathode ray tube with electrical styli imbedded in the front flat portion of the tube. The original system used dry toner and later systems used liquid toner. Total production, to the end of product life in the late 1970's, amounted to about 25 systems in a price range of $250,000 to $500,000. A 30,000 cps direct electrostatic page printer was built by Radiation, Inc. for the Livermore Radiation Laboratory in 1963. It was a high speed dot matrix printer with resolution such that the individual dots were not distinguishable. A commercial vcrsion was never built. The first serial nonimpact printer was introduced in 1965 by NCR. It used heat sensitive paper, which changed color to produce an image. It was first used as a communications terminal by the U.S. Army. ln 1963, R. G. Sweet of Stanford University patented a novel continuous stream inkjet printing system. ln the Sweet method, except where it is desired to print, the ink stream is deflected into a reservoir just before the jet strikes the paper. (see Figure 4) A. B. Dick Company obtained rights under the Sweet patents and subsequently introduced a number of commercial products. ln 1966, Teletype produced a 120 cps inkjet printer called the Inktronic. This 80 colunm non impact printer was intended to replace the older 10 cps impact teleprinters. The Inktronic had 40 jets with each jet printing on two columns. The product proved unreliable and difficult to maintain and was withdrawn. 1970-1979 The emergence of the printer market as a distinct sub-set of the maturating computer market occurred in the mid 1970's. Data on market size from the 1974 calendar year forward is available from industry sources. [Dataquest 1988]. Earlier data, where it exists at aIl, is inconsistent due to lack of standards and generally accepted definitions. Dataquest estimated that a total of 26,000 line printer units were shipped in 1974. Dataproducts production records indicate 5,675 units shipped that year, for a 22% market share. The market more than tripled in the next four years. For 1978, Dataquest estimated unit shipments of 85,000 units. At the time, IBM was the largest supplier of line printers with Dataproducts as the largest independent OEM supplier. Line Printers ln 1970, IBM offered its first band printer. The band was a simplification of the chain/train of the 1960's. Band printers use a steel band font carrier with the characters embossed directly on the band surface. Bands are low cost, lightweight, and are easily changeable by the operator. By the end of the deeade, aIl manufaeturers of fully formed character line printers had switched to the band. Print speeds ranged from 300 to 2400 lpm. ln 1976. Printronix introduced the line matrix printer. Instead of hammers striking moving characters, the font element is a raised dot on the hammer face. After selected hammers strike the paper to create a row of dots, the paper is stepped vertically a small distance and another row of dots printed, etc. An advantage of dot matrix printing was that graphics and text eould be interspersed and printed all in one print run. A disadvantage was poorer individual character quality. Matrix line printers found use for speciality printing applications such as bar codes and industrial labeling. Speeds started at 300 lpm and have climbed to 1200 lpm. Terminals ln 1970, Centronics introduced a seriaI dot matrix impact printer which represented a significant engineering cost/performance breakthrough. This was the Model 101 with a speed of 165 cps using a 5×7 matrix at a selling priee of $3000. (see Figure 5). Both the price and the speed were attractive and the Model 101 soon won acceptance particularly for minicomputers applications. During the 1970's, Centronics became the dominant supplier of seriaI dot matrix printers. While the dot-like structure of the characters was evident and reliability somewhat lower than desired, speed, flexibility and cost effectiveness made the products attractive. By 1976, Centronics had a broad range of product offerings. Other suppliers were attraeted to the serial matrix printer market and soon a range of even lower priced products was available. For example, in the mid-1970's, 150 cps printers sold for less than $2000. By 1979, better machines were being sold for under $1000. Unit volumes rose as prices dropped and, not surprisingly, competition increased. By the late 1970's, the Japanese had become the dominant suppliers of dot matrix printers. [Kilcullen 1988] Dot matrix serial printers did not satisfy the dcmand for print quality, particularly in the office sector. This need engendered a rival serial printer, the daisy wheel. First introduced by Diablo in 1972. the daisy wheel was essentially a high speed typewriter with a font carrier which resembles the petals of a flower. (see Figure 6). The daisy wheel itself is readily operator changeable so that many character sets (but in a limited number of font sizes) may be used. Speed is achieved by constantly rotating the wheel and printing on the fly. The speed of the first Diablo printer was 30 cps. The highest speed reached using this technology was 80 cps. Excellent print quality was achieved and the market for daisy wheel printers grew to 125,000 units shipped in 1978 with an average sales priee of $3,000. Dot matrix print quality remained a problem until near letter quality (NLQ) printing became available in the late 1970's. The early 7 wire heads, were followed by 9-wire, 12 wire, 14 wire and 18-wire heads. When 24-wire heads were introduced in the early 1980's, the print quality achieved became close to that of fully formed characters. ln the 1970's, both NCR and Texas Instruments introduced low cost, lightweight, seriaI teleprinters based on thermal technology. Portable and desktop models were quite successful for a number of years until very low cost impact dot matrix printers eroded their market. Color Printers Color printing became available on impact dot matrix printers in the late 1970's using a four-color ribbon. [Williams 1988]. Overprinting the same dot provided the capability to print up to eight colors. The print quality achieved was adequate but was not equal to that attainable on a number of the nonimpact color printers. Nonimpact printers The first commercially successful direct electrostatic printing . device was announced by Versatec in 1970. It was an 80 column plotter with a resolution of 78.5 dpi and used a special dielectric paper. Versatec subsequently became the dominant supplier of direct electrostatic computer output plotters. [Zaphiropolous 1988]. ln 1972, Mead Digital Systems introduced the DIJIT, a very high speed ink jet printer using deflccted continuous stream ink jets. It printed at 48,000 lpm using a printhead with 100 jets per inch or a resolution of 100 dpi. Its utilization was that of a high-speed printing press controlled from computer output. Xerox delivered the first commercially successful xerography printer, the Model 1200, in 1974. Imaging was from a photographic drum with character images positioned in a manner similar to a line printer drum. Flashes of light were used to transfer the characters to a xerographic printing drum. It printed at 60 shcets per minute or 4,000 lpm using sheet feed 8.5"×11'' paper. The model 1200 was soon superseded by laser printers which had the flexibility of multiple fonts. Also in 1974, Honeywell produced the high speed PPS printer in which direct electrostatic technology was used. The PPS speed was 18,000 lpm and it used a large roll of special dielectric paper which was cut to the desired sheet size after printing. The printer was able to print the form while printing the variable data by using a special forms roll. [Wieselman 1977]. The IBM 3800, announced in 1975, was the first laser driven xerographic printer. (see Figure 7). It used continuous form paper and printed at 13,360 lpm. It had a resolution of only 180×144 dpi which yielded print quality adequate for billing or data processing output but was not letter quality. Forms were created from a forms image roll while printing the variable data at the same time. The next year, 1976, IBM introduced the IBM 6640, the first inkjet printer designed for the office. Based on the Sweet technology, it had a print speed of 92 cps with a resolution of 240 dpi and a selling price of ovcr $20,000. A complete letter could be printed in one run, including lettcrhead sheet, second sheets and envelope. Print quality was acceptable at 240×240 dpi, but not outstanding – due to ink splatter around the printed characters. The 6640 was only mildly successful due to its high price and maintenance problems. ln 1977, Xerox introduced the model 7700 laser xerographic printer, the first of its many models of page printers. The first drop-on-demand inkjet printer was announced by Siemens in 1978 [Johnson 1986]. (see Figure 8). The speed was 270 cps with a resolution of 100 dpi. This was the first of a series of these printers manufactured by Siemens. Other manufacturers, including Japanese, used the same approach and in 1983 color drop-on-demand ink jet printers were introduced. 1980-1989 The most recent decade saw the emergence of the personal computer and the inseparable linkage of computers and communications. Computers and computing have matured to become a major activity worldwide. To the printer industry, maturity has meant consolidation and structural change. Character Printers Decline ln 1982, total equipment revenue for all printers was $12 billion. [Dataquest 1988]. Of this amount, $10.8 billion or about 90% was for impact printers. This share of market declined sharply thereafter. Growth of fully formed line printers had been slowing for some time. Shipments peaked in 1981 at 115,000 units and started to decline thereafter. By 1987, the shift to matrix line printers and the growth of nonimpact page printers, had caused the volume to drop more than 55% to 50,000 nits. The revenue growth of matrix line printers during the same period was dramatic. ln 1978, 10,000 line matrix printers were shipped. This increased to over 50,000 units in 1987. Sales of fully formed daisy wheel printers also declined sharply as NLQ dot matrix printing became acceptable and as non impact technologies became more cost effective. ln 1987, less than 250,000 units were shipped compared with more than 500,000 units in 1981. Dot Matrix Printers Thrive As noted above,demand from the growing personal computer market lowered prices of serial dot matrix machines by the start of the decade. With the introduction in 1982 of the IBM PC computer, prices dropped even more dramatically. Epson, the largest supplier, produced its MX series for the IBM PC in the $500 range. Many other Japanese manufacturers also started to compete in the low price market. ln 1987, over 5,600,000 units were shipped as compared with 200,000 units a decade earlier. Despite the growing popularity of nonimpact printers, the market for serial impact dot matrix printers is the largest in the printer industry [Dataquest 1988]. Personal Laser Printers ln 1983, Canon brought out an inexpensive laser printer. The Canon LPB-CX printed at a speed of eight ppm with a resolution of 300×300 dpi. The print engine was based on the innovative design of their desktop copier in which the photoconductor, electrodes and toner are contained in a disposable cartridge. The print quality is letter quality roughly comparable to a daisy wheel, but with the font flexibility characteristic of matrix printing. The Canon print engine was also sold on an OEM basis to computer companies, among them Hewlett-Packard and Apple, who provide an interface and a controller. The Hewlett-Packard Laserjet has become the de facto standard for low cost laser printers and other manufacturers now provide plug compatible versions. The speed, low noise and print quality made the Laserjet an immediate success and a replacement for the daisy wheel in many installations. ln 1983, under 500 low-speed low-cost laser printers were shipped. The shipment level four years later, in 1987, was 600,000 units. This remains a growing market and Dataquest predicts that shipments will rise to over 2,000,000 units by 1992. High speed Laser Printers The major suppliers of large high speed nonimpact printers are IBM and Xerox. Newer versions of the IBM 3800 are still being manufactured today with higher resolutions and the ability to generate forms on-the-fly from computer software. Xerox has also expanded its product line. The market in 1982 for plain paper page printers was about $400 million. [Dataquest 1988]. That same year, the impact line printer market was four times larger at nearly $1.7 billion. By 1987, the market for non impact page printers was $2.75 billion and line printer unit revenue had dropped to $1.25 billion. Other Page Printers The research and development efforts of the prior decades resulted in a wide variety of nonimpact technologies being brought to the marketplace in the 1980's. An ion deposition printer, the Delphax 2460, was first demonstrated at the 1981 National Computer Conference. It was a plain paper page print engine with a speed of 60 ppm and a resolution of 240 dpi. The technology is known as indirect electrostatic and is similar to direct electrostatic except that the image is formed on a dielectric surface and then transferred to plain paper. A magnetographic page printer was introduced in Europe in 1984 by Bull. These Bull 6000 series machines are designed for heavy duty applications using fanfold pinfeed paper. They print at 60 and 90 ppm with a resolution of 240×240 dpi. The magnetic image is created by a set of 3,360 perpendicular recording heads across the print line and the magnetic image is stored on a 100mm diameter magnetic drum. Monocomponent toner is applied to the drum to develop the image. It is then transferred to paper by light pressure and an electrostatic field and fused by heat. These products have a higher MTBF (mean time between failure) than electrophotographic printers and over 1,000 have been sold world-wide. During the 1970's, thermal printing technology moved from direct thermal, which uses thermal paper, to thermal transfer which uses a thermal ribbon and plain paper. (see Figure 9). Thermal head were developped which spanned the complete print line so that printing could be done in at higher speed in a line printing mode. The paper used is plain paper, but must be of high quality and very smooth in order to achieve good print quality. Thermal color printing is available using four-color ribbons. And the first products using color thermal transfer technology appearèd in 1983 when Toshiba introduccd a wide ribbon printer with three colors capable of printing seven colors at 200×200 dpi in 1 minute. Slower seriaI color thermal printers are also available. ln 1984, IBM introduced the Quietwriter with a new resistive thermal ribbon. This new thermal technology has allowed high print quality printing on a wide variety of papers. This class of printer is vcry quiet and IBM has developed typewriters as well as printers. Two types of ribbons are available, erasable for typewriters and non-erasable for printers. Low cost inkjet printing became available in 1984 when Hewlett-Packard introduced its ThinkJet printer. This uses a drop-on-demand approach, developed by Canon. The disposable printhead consists of twelve chambers. Each of the chambers contains ink, a nozzle and a thin film resistor which when heated causes a small portion of the ink to vaporize. Vapor expansion causes a drop of ink to be expelled from the nozzle. The printer was priced at $500 with a speed of 150 cps with a 11×12 dot character. [Lloyd and Taub 1988] HP has also developed a color version of its Thinkjet product with the ability to generate 550 hues of colors and a speed of 1 page in four minutes. The most recent development in inks for inkjet printers is the use of thermal phase change solid ink. That is, ink which is solid at room temperatures, liquifies quickly when heated and solidifies quickly when cooled. Two solid ink products were introduced in 1986 when Dataproducts announced a black-and-white printer and Howtek announced a color printer. ln 1989, Dataproducts announced a lower cost color printer using this technology. The market for inkjet printers has started to grow. ln 1987, over 200,000 units were shipped and Dataquest predicts that shipments will reach over 1,000,000 units by 1992. Printer Market Directions The computer primer industry is indeed sizeable. It is estimated that in 1989, 8 million units were shipped and that total revenues will be over $21 billion. By 1992, shipments will be close to 10 million units and the total revenues will excecd $25,000 million.[Dataquest 1988] The nonimpact market is experiencing the highest rate of growth and this is expected to continue. Unit shipments for 1992 are expected to be almost twice those of 1989. The decline in shipments of impact printers is expected to continue ovcr the same period. The if-sold value for nooimpact printers is expected to exceed that of the impact printers in 1990. Acknowledgements 1 wish to thank my long time associate Irving L. Wieselman for his leadership role in the research

work from which this paper is drawn. 1 also wish to acknowledge the encouragement and assistance of

Arthur Norberg and William Aspray of the Charles Babbage Institute and thank them for making

available material from an unpublished Charles Babbage Institute paper by Robin Clamons. References Austrian, G.D. 1982. Herman Hollerith. New York, Columbia University Press. Bashe, C.J., L.R. Johnson, J.H. Palmer, and E.W. Pugh, 1986. IBM's Early Computers, Cambridge, Mass., The MIT Press. Clamons, Robin 1988. Unpublished paper "A Historical Survey of the Computer Printer Industry" Minneapolis, Minnesota, Charles Babbage Institute. Dataquest Incorporated 1988. "Electronic Printer Induslry Service" Vol Il, Appendix A, April 1988. Also information published in 1979 and 1983. Dataquest Incorporated 1989. "Personal Computer Industry Service" History Overview, April 1989. Fisher, F.M,, J.W. MeKie, and R.B. Mancke. 1983. IBM and the U.S. Data Processing Industry, New York, Praeger. Johnson, Jerome L. 1986. Principles of Non Impact Printing, Irvine, CA., Palalino Press. Kilcullen, Robert W.Jr. 1988. Personal Interview October 10, 1988. W.J. Lloyd , H. H. Taub 1988, Ink jet printing, Output hardcopy devices, Academic Press Professional, Inc., San Diego, CA, Stone, Joseph J.Jr. 1988. Personal Interview September 9, 1988. Truesdell, L.E. 1965, The Development of Punch Card Tabulation in the Bureau of the Census 1890-1940, Washington D.C., U.S. Government Printing Office. Wieselman, Irving 1975. "Printer Teehology and its Future", Modern Data, November 1975. Wieselman, Irving 1977. "Hard Copy Output and Its future", AFIPS Conference Proceedlngs, Vol 46. Williams, Richard A. 1988. "Wire Matrix Printing" in Durbeck C. and Sol Shen, Output Hardcopy Devices. Boston, Academie Press Inc. Zaphiropolous, Renn 1988. Personal Interview on August 22, 1988. Figures List of figures Figure 1 Drum Printer Mechanism

Figure 1 – Drum Printer Mechanism

Figure 2 – Cylinder Printer Mechanism

Figure 3 – Train Printer Mechanism

Figure 4 – Continuous Stream Inkjet Printer Mechanism

Figure 5 – Impact Serial Dot Matrix Mechanism

Figure 6 – Daisy Whell Printer Mechanism

Figure 7 – Laser Xerographic Printer Mechanism

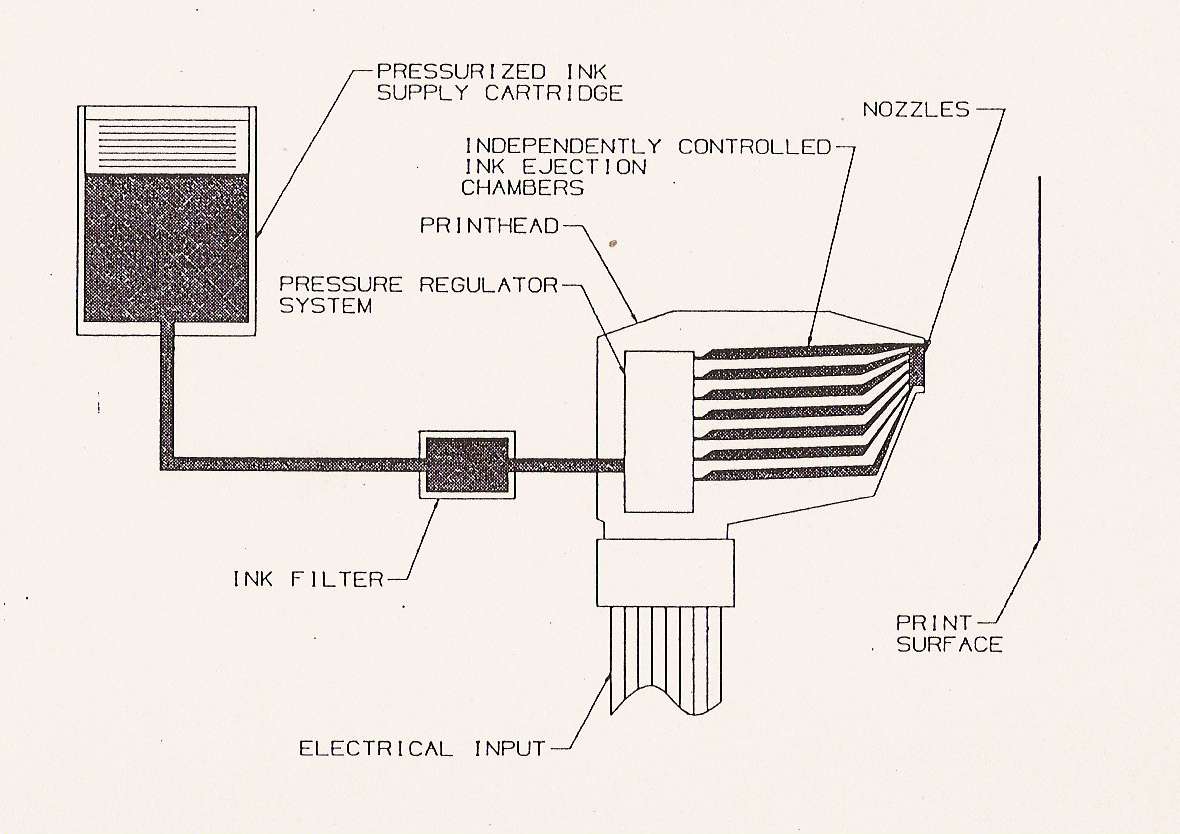

Figure 8 – Drop-On-Demand Inkjet Printer Mechanism

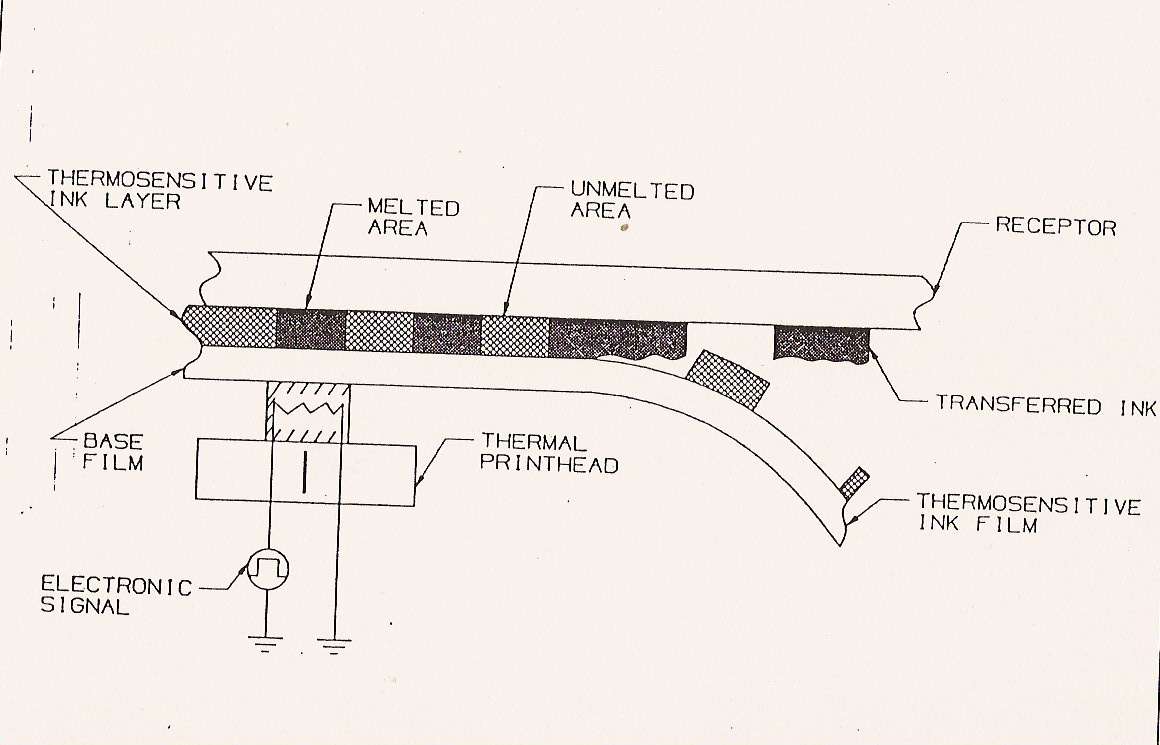

Figure 9 – Thermal Transfer Printer Mechanism Erwin Tomash: biography Erwin Tomash is the Founder of Dataproducts Corporation, a major United States based computer printer manufacturer. He served as Chairman of the Board of Dataproducts from its founding in 1962 until 1980 and as its President from 1962 to 1971. He is currently an Emeritus member of the Board of Directors. Tomash graduated from the University of Minnesota with a B.S. degree in Electrical Engineering (1943) and served as a radar officer in Europe during world War II (Captain, U.S. Army Signal Corps). After the war ended, for a short time he taught Electrical Engineering at the University of Minnesota. ln 1947, he joined Engineering Research Associates (ERA), a pioneer company in the then emerging computer industry. At ERA he played a key role in the development of two, now historic, large scale vacuum tube stored program computers, the ERAllOl and ERA1103. ln 1950, he earned his M.S. in Electrical Engineering from the University of Maryland, and was appointed Assistant Director of Computer Development for ERA that same year. ln 1953, when ERA was acquired by Remington Rand (later UNIVAC), he moved to Los Angeles to set up their first West Coast operation. Two years later, he left Univac to join newly formed Telemeter Magnetics Inc., a pioneer manufacturer of magnetic core memory systems, of which he was elected President in 1956. ln 1961, Telemeter Magnetics merged with Ampex Corporation and Tomash became Vice President and General Manager of Ampex Computer Products Company. He resigned to form Dataproducts Corporation in 1962. Tomash has had a long standing interest in the History of Computing and the impact of the computer on society. He is the founder and Chairman of the Board of Trustees of the Charles Babbage Institute for the History of Information Processing located at the University of Minnesota and a trustee of the Computer Museum in Boston. He and his wife, Adelle, operate Tomash Publishers, Inc. which in conjunction with M.I.T. Press publishes a series of reprints of classic works on the History of Computing. Tomash Publishers aIso issues a similar series on the Historv of Modern Physics in association with the American Institute of Physics. Tomash has authored many papers on various aspects of the computer industry and has been a contributing author to several books on the subject. Tomash currentlv serves as Chairman of the Board of NewPort Corporation, a leading laser research instrumentation manufacturer. He is also a member of the Board of Directors of Supershuttle International, Inc. and Pasqua Inc. He is an Honorary National Governor, past National Chairman and a Director of the CORO Foundation. Tomash serves on the Board of the Los Angeles Educational Partnership and is co-chair of the LAEP Mathematics/Science Task Force. For his military service in World War II, Tomash was awarded the Bronze Star.

Among other honors, he has received the Computer Entrepeneur Award of the Computer Society of the IEEE and the

Outstantding Achievement Award of the University of Minnesota.

He is listed in Who's Who in America. 01/15/90 | ||

|

[Haut de cet article – This paper Top] – Décembre 2006 |